How to select a good machine vision lens?

- Home

- Blog

- Products Information

- How to select a good machine vision lens?

In the entire machine vision system, the machine vision lens is an important imaging componet. So the correct selection of the machine vision lens is very important. With a combination of actual customer cases for many years, the machine vision lens selection considerations as below:

I. Special customer requirements

In general, the special requirements of customers for machine vision lenses should be considered first. Such as whether other devices (lenses, reflective lenses, glass) are added before the machine vision lens and the workpiece.

The following points need to be confirmed first:

1. Requirements for installation space: the size, length, and other parameters of the machine vision lens;

2. Fixed camera hanging lens: For example, some cameras cannot hang heavy machine vision lenses;

3. The camera system needs to move: If the speed is too fast, the camera system may shift due to inertia;

4. There are special requirements for the spectral response. For example, for the ultraviolet environment, ordinary glass lenses will absorb almost all ultraviolet light;

5. Do you need to add a light source to the machine vision lens. According to the scene environment, if you need to increase the brightness, you need to add a light source. If it is a coaxial lens, a point light source can be installed;

6. Price requirements;

7. Working environment of machine vision lens;

8. Whether there are other special components.

II.Do you need a telecentric lens?

Telecentric lenses are required for precision measurement systems. The main function of a telecentric lens is to overcome the effect of perspective phase difference (inconsistent magnification due to different distances during imaging), so that the size data obtained when the detection target moves within a certain range is almost unchanged.

In general, telecentric lenses have a fixed focal length and working distance, and some telecentric lenses are large in size and some weigh more than ten pounds. You need to understand the customer ’s view of the field of view size, working distance, space restrictions, and The requirements of motion control can be determined after the required lens model specifications.

When there is no strict requirement on the imaging of objects such as general surface defect detection and judgment, use a telecentric lens with less distortion.

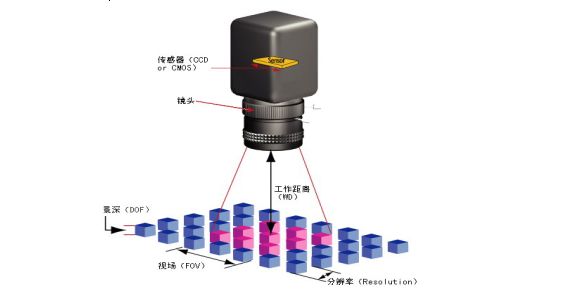

III. The depth of field of the machine vision lens

Some vision systems with special requirements require lenses with a relatively large depth of field. For example, in some inspections or measurements, an industrial camera must be angled and the entire object must be clearly imaged; the measured targets are not on the same plane, which requires the depth of field of the lens to be considered.

The shorter the focal length, the greater the depth of field; the smaller the aperture, the greater the depth of field; the farther the lens is from the object, the greater the depth of field; the small aperture and good light make focusing easier, but the small aperture will lose the fine structure of the object. The larger the camera chip, the greater the depth of field.

IV. The chip size of the machine vision lens

Each machine vision lens can only be compatible with cameras whose chips do not exceed a certain size. Therefore, when selecting a machine vision lens, you must first determine the chip size of the industrial camera. In order to ensure the quality of the entire image, the maximum chip size of the machine vision lens must be larger than the matching chip size, otherwise it will cause serious distortion and phase difference.

V. The interface of the machine vision lens

Machine vision lens interfaces and camera interfaces are divided into C, CS, F and other larger size interface types. Cameras and lenses are complementary, that is, C-mount cameras can only use C-mount lenses.

VI. The focal length of the machine vision lens

The focal length of the lens has a major impact on the field of view and working distance. Factors such as field of view, working distance, and camera chip size must be determined before determining the focal length of the machine vision lens.

Distortion of machine vision lens

Distortion is image distortion caused by inconsistent local magnification in the field of view. Due to the influence of the production process, lens distortion is inevitable. The better the lens, the smaller the distortion. Generally, in the case of high accuracy requirements such as precision measurement systems, the distortion of the machine vision lens must be considered.

These lens parameters must be selected based on the actual project.

If you need any lens consultant, please contact us